在线提供 29 June 2022

Abstract

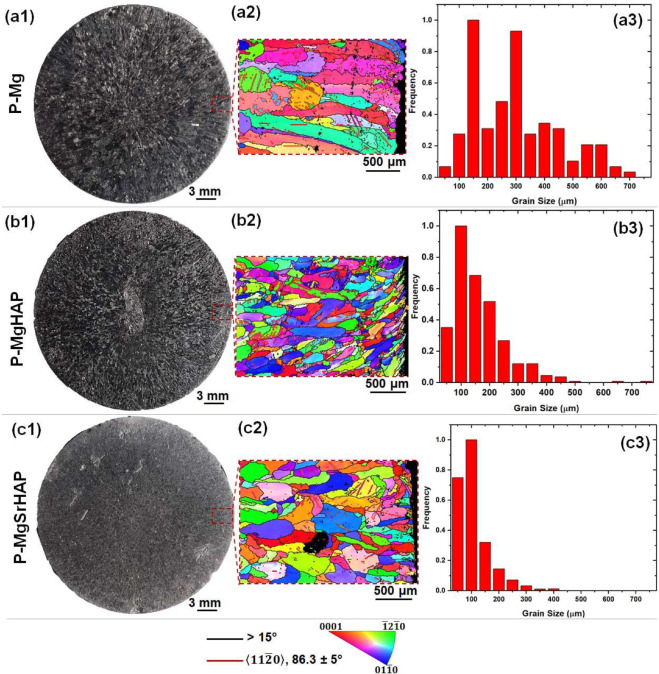

Magnesium-based

biomaterials have been in extensive research for orthopedic

applications for decades due to their optimal mechanical features and

osteopromotive nature; nevertheless, rapid degradation restricts their

clinical applicability. In this study, pristine magnesium was purified

(P-Mg) using a melt self-purification approach and reinforced using

indigenously synthesized nanohydroxyapatite (HAP, 0.6 wt.%) and

strontium substituted nanohydroxyapatite (SrHAP, 0.6 wt.%) using a

low-cost stir assisted squeeze casting method to control their

degradation rate. Using electron back-scattered diffraction (EBSD) and

X-ray diffraction (XRD) examinations, all casted materials were

carefully evaluated for microstructure and phase analysis. Mechanical

characteristics, in vitro degradation, and in vitro biocompatibility with murine pre-osteoblasts were also tested on the fabricated alloys. For in vivo examination of bone formation, osteointegration, and degradation rate,

the magnesium-based alloys were fabricated as small cylindrical pins

with a diameter of 2.7 mm and a height of 2 mm. The pins were implanted

in a critical-sized defect in a rat femur shaft (2.7 mm diameter and

2 mm depth) for 8 weeks and evaluated by micro-CT and histological

evaluation for bone growth and osteointegration. When compared to P-Mg

and P-MgHAP, micro-CT and histological analyses revealed that the

P-MgSrHAP group had the highest bone formation towards the periphery of

the implant and hence maximum osteointegration. When the removed pins

from the bone defect were analyzed using GIXRD, they displayed

hydroxyapatite peaks that were consistent with bio-integration. For

P-Mg, P-MgHAP, and P-MgSrHAP 8 weeks after implantation, in vivo degradation rates derived from micro-CT were around 0.6 mm/year,

0.5 mm/year, and 0.1 mm/year, respectively. Finally, P-MgSrHAP possesses

the requisite degradation rate as well as sufficient mechanical and

biological properties, indicating that it has the potential to be used

in the development/fabrication of biodegradable bioactive orthopaedic

implants.

Keywords