Jiangfeng Song, Jia She, Daolun Chen, Fusheng Pan

Jiangfeng Song, Jia She, Daolun Chen, Fusheng Pan

10 August 2021

10 August 2021

This review paper is aimed to summarize the latest important advances in cast magnesium alloys, wrought magnesium alloys and functional magnesium materials worldwide in 2018 2019, including both the development of new materials and the innovation of their processing technologies. Based on the issues and challenges identified here, some future research directions are suggested,including further development of high-performance magnesium alloys having high strength and superior plasticity together with high corrosion resistance and low cost, and fundamental research on the phase diagram, diffusion,precipitation, etc., as well as the development of advanced welding and joining technology.

More and more scientists and researchers joined in the research and development of magnesium and its alloys in the world due to the increasing importance of magnesium and its alloys. A large number of new magnesium alloys have been developed. Among them, MG9999, MAQ80, MAL32, MAT11, MAT61, MAJ31, MAZ31c,MVWZ641, MVWE751, MVW83, MVWZ842, MVK41, MLAZ433, MLAZ1033, MWEK711, MWEK911,MZAC811, MZC20, MZME210, MZM51 from China, MWE43c, MVW76 from the United Kingdom, and MAX51, MAX61, MAX62, MAM60, MAZ91, MAXZ311, MAXZ611, MXAZ621,MAXZ811, MAXZ911, MAXZ921, MLZ91, MWZ73, MWZ75 from Japan were newly collected in the recently published ISO 3116:2019 (5th edition).

With further research on the precipitation strengthening and fine grain strengthening, the strength (especially the yield strength) of magnesium alloys is greatly improved in 2018–2019. For some high strength magnesium alloys, the ultimate tensile strength has exceeded 560 MPa, and the yield strength has surpassed 540 MPa. The development of rare earth free and low rare earth high strength magnesium alloys is more prominent, such as Mg–5Al–3Ca–0.3Mn alloy exhibits a yield strength of 420 MPa, an ultimate tensile strength of 451 MPa and an elongation to failure of 4.1%.

The proposed theory of solid solution strengthening and ductilizing (SSSD) provided an important theoretical basis for the development of high plasticity magnesium alloys, and provided a new solution to the balance between strength and plasticity of magnesium alloys. The development of high plasticity magnesium alloys has made an important breakthrough in 2018–2019 with comprehensive applications of the SSSD, grain refinement and controlling of long-period stacking ordered structure. A batch of high plasticity magnesium alloys exhibited great potential in industrial applications, such as low cost Mg–1Mn–0.5Al alloy showed an ultimate tensile strength of 263 MPa and a high elongation of 33.4%.

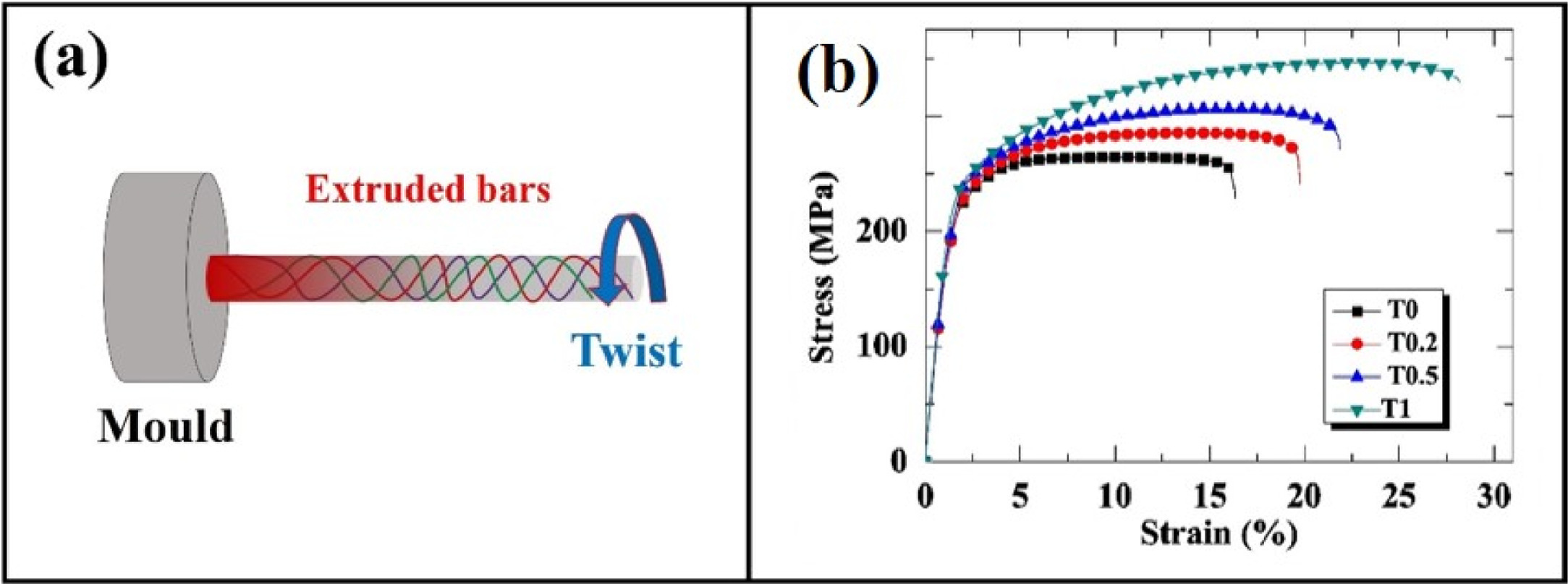

The preparation and processing technologies of magnesium alloys have been further improved in 2018–2019. Among them, both the theory and technology of asymmetric processing technology have made a new breakthrough. Some of new preparation and processing technologies show important prospects, such as melt self-purification, magnetic assisted solidification, low temperature extrusion,on-line twist extrusion, hard pate rolling, composite extrusion, etc.

(a)Schematic diagram of OLTE process and (b) stress–strain curves of ZK60 alloys

Magnesium matrix composites are expected to provide a new pathway for improving the strength and elastic modulus of magnesium alloys. In 2018–2019, the published results have shown that SiC-reinforced AZ91 alloy exhibited a high strength of ∼441 MPa and a high elastic modulus of ∼60 GPa.

Functional magnesium materials have demonstrated great potential and will become a hot spot in the breakthrough and application of magnesium and magnesium alloys. Among them, hydrogen storage Mg materials, battery Mg materials, bio-Mg materials,etc., have made rapid progresses, which have already exhibited advantages in competition with the traditional materials. Hence, functional magnesium materials are anticipated to become an important growth point in the field of new magnesium materials.

The schematic illustration of rechargeable magnesium battery

Compared with traditional materials such as steel and Al, the comprehensive properties of magnesium alloys need to be further improved. For example, the ultimate tensile strength and plasticity of ultra-high strength cast magnesium alloys must be increased to more than 400 MPa, 7–10%, respectively. The ultimate tensile strength and the plasticity of ultra-high strength wrought magnesium alloys must be increased to more than 600 MPa and 7–10%, respectively. The elastic modulus of high elastic modulus magnesium alloys must be enhanced to the level close to that of aluminum alloys. The corrosion resistance of high corrosion resistant magnesium alloys must be improved to meet the application requirements in most occasions.

The fundamental research on magnesium and magnesium alloys needs to be further strengthened. For instance, accurate phase diagrams of magnesium alloys are awfully insufficient; fundamental data such as diffusion coefficient, thermal conductivity, activity coefficient, etc., of magnesium alloys are also scarce;the basic research on a variety of precipitates and their precipitation mechanisms including various phase relationships is limited; and the development of welding and joining technology in magnesium alloy parts especially more challenging dissimilar welding of magnesium alloys to other materials such as steels and aluminum alloys is also inadequate. It is hoped that most of these pressing issues can be solved in the next five years or so, so as to promote vigorously the widespread industrial applications of lightweight magnesium alloys.